Exploring the Significance of German DIN Fittings in Modern Business

German DIN fittings have become synonymous with quality, reliability, and precision in the industrial landscape. These fittings play a pivotal role in various sectors, including manufacturing, engineering, automotive, and construction. This article will delve into the myriad uses of German DIN fittings, their advantages, the standards that govern them, and why they should be an integral part of your business operations.

What are German DIN Fittings?

German DIN fittings refer to a class of connectors and fasteners that adhere to the standards set by the Deutsches Institut für Normung (DIN) in Germany. These fittings are designed to facilitate seamless connections within various systems, ensuring both efficiency and safety. The DIN standards cover a wide array of components, including but not limited to:

- Pipes

- Flanges

- Bolts and nuts

- Gaskets

- Fittings

The Importance of DIN Standards

The significance of German DIN fittings is heavily rooted in the standards they comply with. DIN standards are revered worldwide for their ability to enhance safety, performance, and interoperability. Here’s why they matter:

1. Quality Assurance

Products that meet DIN standards are thoroughly tested to ensure they fulfill stringent quality criteria. This quality assurance means that businesses can count on the reliability of the fittings they use, leading to reduced downtime and maintenance costs.

2. Interoperability

With numerous industrial equipment and technologies relying on DIN standards, it is easy to find compatible components. This interoperability is crucial for businesses looking to upgrade their systems without completely overhauling existing infrastructures.

3. Global Recognition

DIN standards are recognized globally, which means that products manufactured according to these standards can be sold and used in multiple markets. This global acceptance enhances trade opportunities for businesses and assists in building international client relationships.

The Versatility of German DIN Fittings

One of the most compelling advantages of German DIN fittings is their versatility. They can be used across various applications, including:

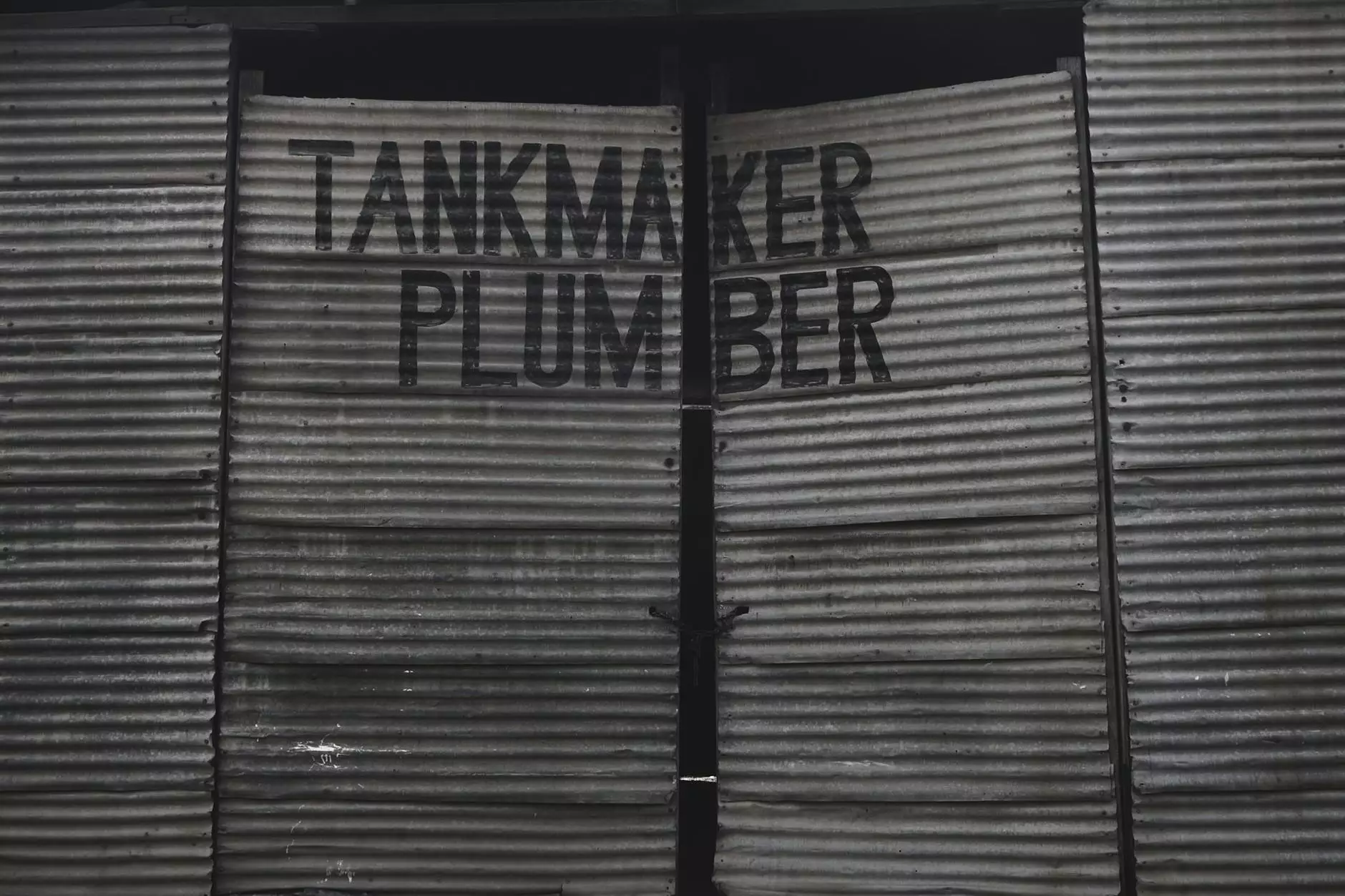

1. Plumbing and HVAC Systems

In plumbing and HVAC (Heating, Ventilation, and Air Conditioning) systems, DIN fittings are essential for ensuring leak-proof connections. They help maintain proper pressure levels and facilitate effective heat transfer in heating systems.

2. Automotive Industry

German engineering is renowned for automotive quality, and DIN fittings are no exception. They are used extensively in vehicle assembly to connect components like exhaust systems and air intakes, ensuring safety and performance on the roads.

3. Manufacturing and Fabrication

Manufacturers utilize DIN fittings to create robust assembly lines and equipment. Their standardization allows for easier upgrades and integration of new technologies, contributing to overall productivity and efficiency.

4. Construction

In the construction sector, German DIN fittings facilitate reliable connections in scaffolding, piping, and structural supports. Their durability ensures that they can withstand the rigorous demands of construction sites.

Types of German DIN Fittings

Understanding the different types of German DIN fittings can help businesses make informed decisions when sourcing components. Below are some of the commonly used fittings:

1. DIN Flanges

DIN flanges are critical in connecting pipes, pumps, and valves. They come in various sizes and pressure ratings and ensure that connections remain secure under various operational conditions.

2. DIN Bolts and Nuts

These fasteners are essential for securing components together. They must withstand significant stresses and strains, thereby ensuring that machinery and structures remain intact and functional.

3. DIN Gaskets

Gaskets manufactured to DIN standards play an essential role in preventing leakage between flanged connections. They provide a seal that can withstand high temperatures and pressures, crucial in HVAC and piping applications.

4. DIN Fittings for Fluid Handling

These fittings are used in systems where liquids and gases are transported. They ensure that system integrity is maintained while allowing for the efficient flow of materials.

How to Choose the Right German DIN Fittings?

Selecting the correct German DIN fittings is crucial for ensuring that the intended application is safe and effective. Here are essential considerations:

- Material Compatibility: Ensure that the material of the fitting matches the media being transported (e.g., water, gas, chemicals).

- Pressure Ratings: Confirm that the fittings can withstand the pressures of your system.

- Size and Dimensions: Choose fittings that fit well within your existing setup without the need for modifications.

- Compliance with Standards: Verify that the fittings meet the relevant DIN standards applicable to your industry.

- Supplier Reputation: Source your fittings from reputable suppliers, such as fitsch.cn, who guarantee quality and reliability.

Benefits of Using German DIN Fittings in Your Business

Incorporating German DIN fittings into your business operations offers numerous benefits that enhance productivity and safety:

1. Enhanced Durability

Products that adhere to DIN standards are designed for longevity, which translates into long-term savings and reduced need for replacements and repairs.

2. Improved Safety

Using standardized fittings minimizes the risk of leaks, failures, and associated hazards, ensuring a safer working environment for employees.

3. Increased Efficiency

Standardization fosters easier assembly and maintenance, allowing businesses to operate more efficiently and reduce downtime.

4. Cost-Effective Solutions

Though the initial investment might be higher, the long-term benefits of using German DIN fittings outweigh the costs through reduced maintenance and replacement expenses.

Conclusion

In conclusion, German DIN fittings represent a vital component in the machinery and equipment that insists on quality and reliability. As industries continue to evolve, the demand for standardized fittings that meet internationally recognized specifications will only rise. Businesses looking to optimize their operations and enhance safety should make a concerted effort to incorporate these fittings into their processes. With their proven track record and multitude of benefits, German DIN fittings are not just an option; they are imperative for achieving success in today's competitive landscape.